Future Trends: The Impact of Technological Advances on Well Control Hoses in Oil Extraction

Introduction:

The oil extraction industry has always been at the forefront of technological advancements. As the demand for oil continues to rise, the need for more efficient and safe extraction methods becomes paramount. Well control hoses, a critical component in oil extraction operations, are not exempt from this trend. In this article, we will explore the future trends and the impact of technological advances on well control hoses in oil extraction.

Technological Advancements:

Advancements in technology have revolutionized the design and functionality of well control hoses. Traditional hoses have often faced challenges such as limited durability, susceptibility to extreme weather conditions, and difficulties in monitoring crucial parameters. However, with the advent of innovative technologies, these limitations are being overcome.

Enhanced Durability and Reliability:

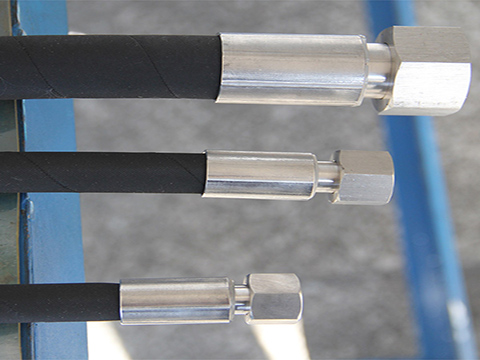

Modern well control hoses are now being built with superior materials and reinforced structures, ensuring enhanced durability and reliability. These hoses are designed to withstand high pressures, extreme temperatures, and harsh environmental conditions often encountered during oil extraction operations.

Smart Hoses:

The integration of smart technologies has transformed well control hoses into intelligent systems. Embedded sensors and monitoring devices now allow real-time monitoring of critical parameters such as pressure, temperature, and flow rates. This enables early detection of potential issues, allowing for prompt preventive actions and minimizing the risk of accidents.

Smart Hoses:

The integration of smart technologies has transformed well control hoses into intelligent systems. Embedded sensors and monitoring devices now allow real-time monitoring of critical parameters such as pressure, temperature, and flow rates. This enables early detection of potential issues, allowing for prompt preventive actions and minimizing the risk of accidents.

Impact on Oil Extraction Operations:

The advancements in well control hose technology have significant implications for oil extraction operations.

Safety Improvements:

With real-time monitoring capabilities, any abnormal conditions or potential failures can be immediately detected and addressed. This enhances safety for both workers and the environment. Timely detection of leaks or pressure irregularities reduces the risk of blowouts and other accidents, mitigating potential disasters.

Impact on Oil Extraction Operations:

The advancements in well control hose technology have significant implications for oil extraction operations.

Safety Improvements:

With real-time monitoring capabilities, any abnormal conditions or potential failures can be immediately detected and addressed. This enhances safety for both workers and the environment. Timely detection of leaks or pressure irregularities reduces the risk of blowouts and other accidents, mitigating potential disasters.

Increased Efficiency:

The durability and reliability of modern well control hoses minimize downtime due to maintenance and replacement. This improves overall operational efficiency by reducing the time and costs associated with hose failures. Additionally, real-time monitoring allows for better control and optimization of drilling processes, leading to increased productivity and cost-effectiveness.

Increased Efficiency:

The durability and reliability of modern well control hoses minimize downtime due to maintenance and replacement. This improves overall operational efficiency by reducing the time and costs associated with hose failures. Additionally, real-time monitoring allows for better control and optimization of drilling processes, leading to increased productivity and cost-effectiveness.

Conclusion:

Technological advancements continue to revolutionize the oil extraction industry. The impact of these advances on well control hoses cannot be understated. With enhanced durability, real-time monitoring, and improved safety measures, these hoses are becoming more efficient, reliable, and cost-effective. As oil extraction operations become increasingly complex, the integration of advanced technologies in well control hoses will play a crucial role in ensuring safe and efficient operations for the future.

Conclusion:

Technological advancements continue to revolutionize the oil extraction industry. The impact of these advances on well control hoses cannot be understated. With enhanced durability, real-time monitoring, and improved safety measures, these hoses are becoming more efficient, reliable, and cost-effective. As oil extraction operations become increasingly complex, the integration of advanced technologies in well control hoses will play a crucial role in ensuring safe and efficient operations for the future.

Leave Your Product Requirements

Your email address will not be published. Required fields are marked *