Chemical Transfer Hoses: Ensuring Compliance with Safety Regulations and Standards

Introduction:

Chemical transfer hoses play a crucial role in industries that handle hazardous materials. The safe and efficient transfer of chemicals relies on the proper selection, installation, and maintenance of these hoses. Ensuring compliance with safety regulations and standards is essential to protect workers and the environment. This article will delve into the importance of adhering to safety guidelines and outline the key factors to consider when using chemical transfer hoses.

Meeting Safety Regulations and Standards:

In industrial settings, safety regulations and standards are in place to prevent accidents and protect workers. Chemical transfer hoses must comply with these guidelines to ensure safe operations. Adhering to safety regulations not only safeguards employees but also minimizes the risk of environmental contamination. Compliance ensures that the hoses are designed and manufactured to withstand the specific pressures, temperatures, and chemical compositions they will encounter during use.

Factors to Consider:

Hose Material: Selecting the appropriate hose material is crucial. Different chemicals require different materials to resist degradation and maintain structural integrity. Conduct thorough research to determine the compatibility between the hose material and the chemicals being transferred. Additionally, consider the temperature range and pressure ratings required for the specific application.

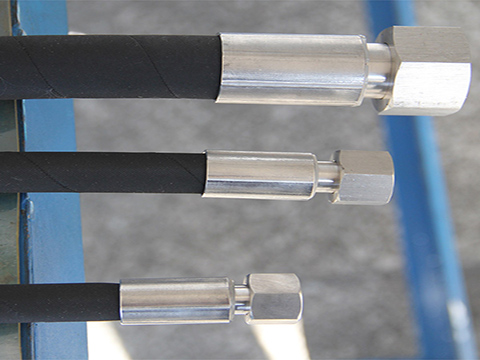

Hose Design and Construction: The design and construction of chemical transfer hoses should meet industry standards and regulations. Look for hoses that are flexible yet robust, allowing for easy maneuverability while withstanding the demands of the application. Reinforcement layers, such as braids or spirals, enhance strength and durability.

Regular Inspection and Maintenance: Regular inspection and maintenance are essential to ensure the continued safe and efficient operation of chemical transfer hoses. Inspect hoses for signs of wear, such as cracks, bulges, or leaks. Replace any damaged hoses immediately. Regularly check fittings and connections for tightness and integrity. Follow manufacturer guidelines for maintenance procedures and recommended replacement intervals.

Training and Education: Proper training and education are vital for all personnel involved in the handling and use of chemical transfer hoses. Ensure that employees understand the risks associated with chemical transfers and are trained in the correct handling procedures. This includes proper hose assembly, connection, disconnection, and storage techniques. Ongoing training keeps employees updated on the latest safety protocols.

Conclusion:

Adhering to safety regulations and standards is paramount when working with chemical transfer hoses. These hoses are critical components in industries where the handling of hazardous chemicals is common. Compliance with safety guidelines ensures the protection of workers and the environment. By considering factors such as hose material, design, maintenance, and training, industries can prioritize safety and maintain efficient operations in chemical transfer processes.

Leave Your Product Requirements

Your email address will not be published. Required fields are marked *