Exploring the Manufacturing Process of Steel Wire Wrapped Hydraulic Pipes

Introduction

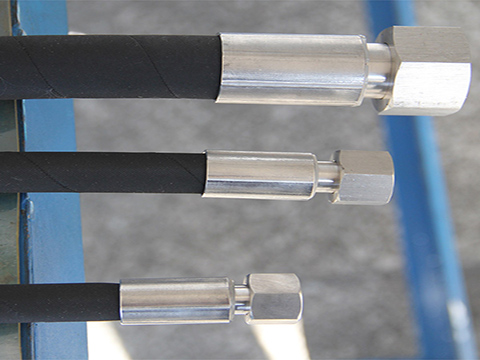

Steel wire wrapped hydraulic pipes play a crucial role in the smooth operation of various industrial machinery. These pipes are designed to withstand high pressure and deliver hydraulic fluids efficiently. In this article, we will delve into the manufacturing process of these essential components, highlighting the steps involved and the importance of quality control.

Production Steps

The manufacturing process of steel wire wrapped hydraulic pipes involves several key steps. Firstly, high-quality steel rods are selected, ensuring optimal strength and durability. These rods are then cut into the desired length and heated to the appropriate temperature for further processing. Next, the heated rods are shaped into seamless pipes using a combination of extrusion and rolling techniques. This process ensures a consistent diameter and smooth surface finish.

After the pipes are formed, they undergo an inspection to ensure they meet the required specifications. This includes checking for any defects, such as cracks or irregularities, that may compromise the integrity of the pipes. Once the inspection is complete and the pipes pass the quality standards, they proceed to the next stage.

The next step in the manufacturing process involves wrapping the steel pipes with high-tensile steel wire. This wire is precisely wound around the pipes, providing additional strength and reinforcement. It acts as a protective layer, enhancing the pipes' resistance to external forces and preventing potential damage during operation. The wire wrapping process requires careful precision to ensure uniform coverage and proper adhesion between the wire and the pipe's surface.

After the pipes are formed, they undergo an inspection to ensure they meet the required specifications. This includes checking for any defects, such as cracks or irregularities, that may compromise the integrity of the pipes. Once the inspection is complete and the pipes pass the quality standards, they proceed to the next stage.

The next step in the manufacturing process involves wrapping the steel pipes with high-tensile steel wire. This wire is precisely wound around the pipes, providing additional strength and reinforcement. It acts as a protective layer, enhancing the pipes' resistance to external forces and preventing potential damage during operation. The wire wrapping process requires careful precision to ensure uniform coverage and proper adhesion between the wire and the pipe's surface.

Quality Control

Quality control is paramount in the manufacturing of steel wire wrapped hydraulic pipes. Throughout the process, rigorous inspections are conducted to identify any defects or deviations from the required standards. This includes dimensional checks, tensile strength testing, and surface inspections. Additionally, hydraulic pressure tests are performed to verify the pipes' ability to withstand the specified pressure levels without leakage or failure.

Conclusion

The manufacturing process of steel wire wrapped hydraulic pipes involves careful selection of materials, precise shaping, and meticulous quality control measures. These pipes play a vital role in various industrial applications, ensuring the smooth transmission of hydraulic fluids under high pressure. By understanding the intricacies of their production, we can appreciate the level of expertise and attention to detail required to produce these essential components.

Quality Control

Quality control is paramount in the manufacturing of steel wire wrapped hydraulic pipes. Throughout the process, rigorous inspections are conducted to identify any defects or deviations from the required standards. This includes dimensional checks, tensile strength testing, and surface inspections. Additionally, hydraulic pressure tests are performed to verify the pipes' ability to withstand the specified pressure levels without leakage or failure.

Conclusion

The manufacturing process of steel wire wrapped hydraulic pipes involves careful selection of materials, precise shaping, and meticulous quality control measures. These pipes play a vital role in various industrial applications, ensuring the smooth transmission of hydraulic fluids under high pressure. By understanding the intricacies of their production, we can appreciate the level of expertise and attention to detail required to produce these essential components.

Leave Your Product Requirements

Your email address will not be published. Required fields are marked *