Understanding Maximum Pressure Ratings for Hydraulic Hoses

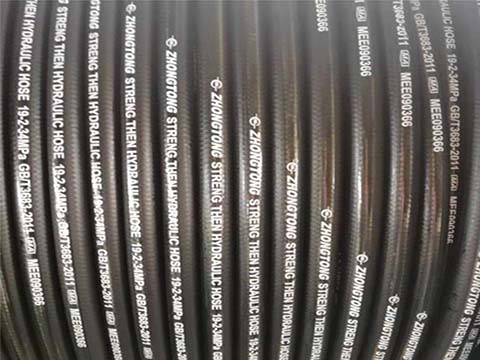

Hydraulic hoses are essential components in a wide range of industrial and commercial applications. They are used to transfer hydraulic fluid between different components in a hydraulic system, such as pumps, valves, cylinders, and motors. One of the key factors to consider when selecting a hydraulic hose is the maximum pressure rating.

The maximum pressure rating of a hydraulic hose is the highest amount of pressure that the hose can withstand before it fails. This is typically measured in pounds per square inch (PSI) or bar. The maximum pressure rating is based on a number of factors, including the size of the hose, the material it is made from, and the reinforcement used to reinforce the hose.

It is important to choose a hydraulic hose with a maximum pressure rating that exceeds the maximum operating pressure of the hydraulic system it will be used in. Operating a hydraulic hose at or near its maximum pressure rating can lead to premature failure, which can result in costly downtime and repairs.

When selecting a hydraulic hose, it is also important to consider factors such as the temperature range it can operate in, the compatibility of the hose with the hydraulic fluid being used, and any environmental factors that may affect the hose's performance.

Regular inspection and maintenance of hydraulic hoses is also essential to ensure that they continue to operate safely and reliably. Hoses should be inspected regularly for signs of wear, damage, or leaks. Any damaged or worn hoses should be replaced immediately to prevent failure and potential safety risks.

In summary, understanding the maximum pressure rating of hydraulic hoses is essential to ensuring their safe and reliable operation in hydraulic systems. When selecting a hydraulic hose, it is important to choose one with a maximum pressure rating that exceeds the maximum operating pressure of the system it will be used in. Regular inspection and maintenance of hydraulic hoses is also important to prevent failures and ensure safe operation.

The maximum pressure rating of a hydraulic hose is the highest amount of pressure that the hose can withstand before it fails. This is typically measured in pounds per square inch (PSI) or bar. The maximum pressure rating is based on a number of factors, including the size of the hose, the material it is made from, and the reinforcement used to reinforce the hose.

It is important to choose a hydraulic hose with a maximum pressure rating that exceeds the maximum operating pressure of the hydraulic system it will be used in. Operating a hydraulic hose at or near its maximum pressure rating can lead to premature failure, which can result in costly downtime and repairs.

When selecting a hydraulic hose, it is also important to consider factors such as the temperature range it can operate in, the compatibility of the hose with the hydraulic fluid being used, and any environmental factors that may affect the hose's performance.

Regular inspection and maintenance of hydraulic hoses is also essential to ensure that they continue to operate safely and reliably. Hoses should be inspected regularly for signs of wear, damage, or leaks. Any damaged or worn hoses should be replaced immediately to prevent failure and potential safety risks.

In summary, understanding the maximum pressure rating of hydraulic hoses is essential to ensuring their safe and reliable operation in hydraulic systems. When selecting a hydraulic hose, it is important to choose one with a maximum pressure rating that exceeds the maximum operating pressure of the system it will be used in. Regular inspection and maintenance of hydraulic hoses is also important to prevent failures and ensure safe operation.

Leave Your Product Requirements

Your email address will not be published. Required fields are marked *